How a Strong FEED Phase Cuts Cost Overruns and Design Changes in Oil & Gas Projects

1. What Is FEED — and Why It Matters

FEED bridges conceptual studies and EPC execution. Its purpose is to mature the project definition to roughly 30% design completion and produce Class-3 cost estimates (±15–30%).

Core FEED Deliverables

A complete FEED package typically includes:

- Process Flow Diagrams (PFDs)

- 60–80% developed P&IDs

- Equipment lists and datasheets

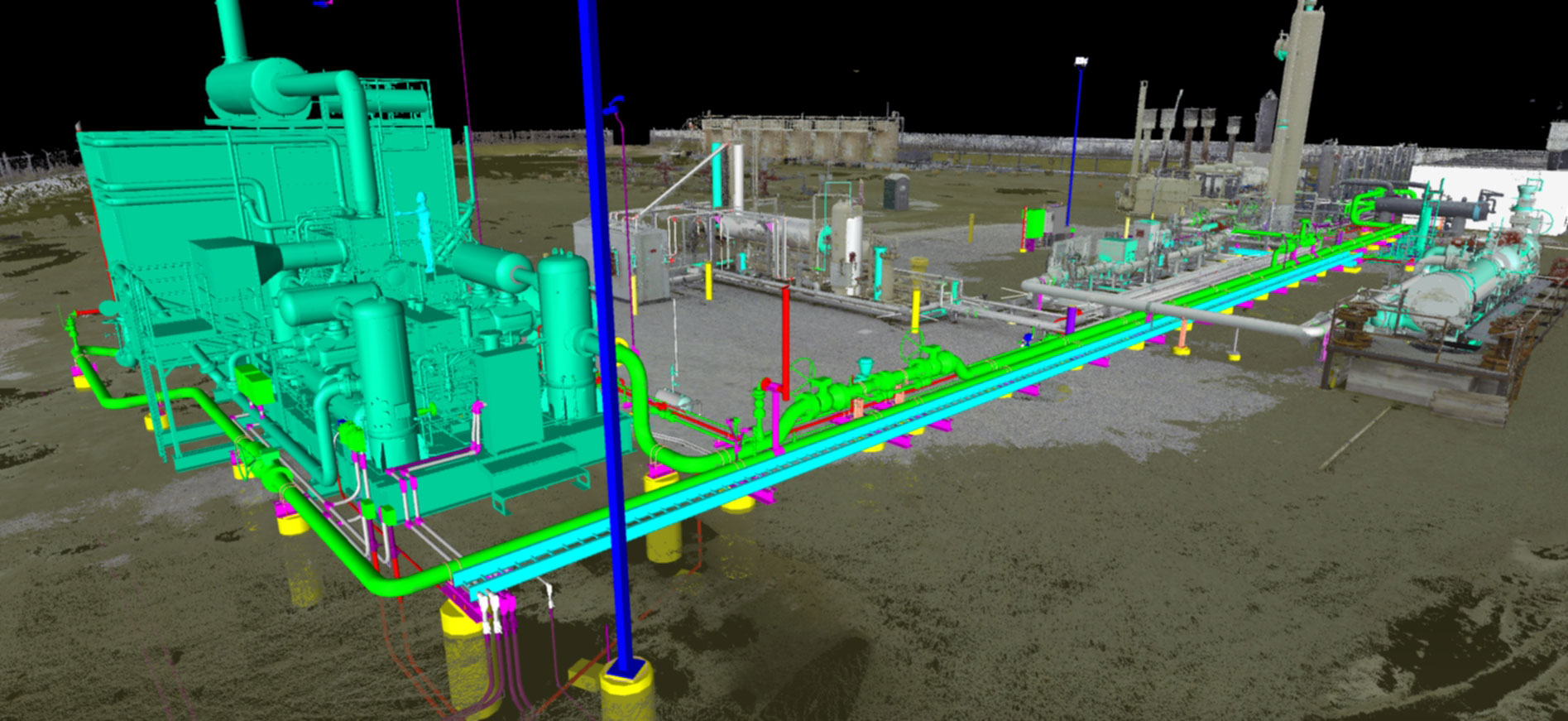

- Plot plans and preliminary 3D models

- HAZOP and safety studies

- Risk registers and constructability reviews

- Procurement strategies

- Bid-ready EPC documentation

Unlike early FEL stages, FEED performs quantified trade-offs between:

- CAPEX vs OPEX

- Safety vs operability

- Reliability vs constructability

For asset integrity teams, FEED is also where Risk-Based Inspection (RBI) frameworks are embedded—assigning corrosion mechanisms, H₂S cracking risks, and inspection baselines before steel is even ordered.

2. Why Projects Overrun: The Anatomy of Weak FEED

Poor FEED creates downstream chaos.

Independent audits show that:

- ~80% of cost overruns stem from inadequate early planning

- Large oil & gas projects average 20–30% budget blowouts when FEL/FEED quality is low

Typical Failure Points

| Gap | Impact |

|---|---|

| Incomplete geotechnical surveys | Foundation redesigns (10–15% cost hit) |

| Limited constructability input | Piping quantities rise 20–25% |

| Over-specification | 10–20% wasted on oversized equipment |

| Late stakeholder alignment | Scope creep adds ~15% |

| Deferred safety studies | Expensive redesign during EPC |

3. Design Change Dynamics — and How Strong FEED Prevents Them

Projects without rigorous FEED experience 20–50% more design changes, driven by:

- Interface clashes

- Regulatory surprises

- Missing operability requirements

- Late safety discoveries

Offshore, a single piping clash can cost $1M+ per day. Late SIL or HAZOP findings often force valve replacements, control logic changes, and layout revisions.

Strong FEED Countermeasures

- Early 3D clash detection (cuts design changes ~40%)

- Iterative HAZOP + QRA workshops

- Value engineering sessions

- Specification freeze after gated reviews

- Multidisciplinary constructability modeling

4. Quantified Benefits of a High-Quality FEED

Here’s what best-in-class FEED consistently delivers:

| Benefit | Mechanism | Typical Impact |

|---|---|---|

| Cost Accuracy | Class-3 estimates | 20–30% overrun avoidance |

| Risk Reduction | HAZOP + SIL integration | Up to 80% fewer safety reworks |

| Schedule Gains | Constructability modeling | 3–6 months saved |

| Better EPC Bids | Clear tender packages | 10–15% lower bids |

| Lifecycle Optimization | RBI + maintainability | ~15% OPEX reduction |

| Expansion Readiness | Modular layouts | 25% faster brownfield upgrades |

Despite representing only 4–8% of total CAPEX, FEED often delivers 5–10× ROI.

5. Lessons from Major Projects

Chevron Gorgon LNG

Poor FEL quality contributed to $10B+ overruns (~30%). Post-project analysis showed that even average FEED rigor could have saved ~7% of total CAPEX.

Shell Prelude FLNG

Rushed early engineering and incomplete stakeholder alignment led to 32% cost escalation.

Oyu Tolgoi (cross-industry parallel)

Weak geological FEED caused a 32% cost spike, reinforcing how early definition governs megaproject outcomes.

In contrast, Middle East gas developments using advanced FEED risk modeling achieved:

- ~20% CAPEX savings

- ~6 months schedule acceleration

- Avoided $100M+ in rework

6. FEED + Asset Integrity: Designing Reliability from Day One

Modern FEED integrates integrity engineering:

- Early identification of damage mechanisms

- RBI planning aligned with design

- Corrosion-resistant material selection

- Access for inspection and maintenance

Standards such as API 581 enable inspection strategies to be engineered directly into layouts—reducing lifetime operating costs and unplanned outages.

7. Digital FEED: AI and Digital Twins Enter the Mainstream

FEED is rapidly becoming digital-first.

Emerging Capabilities

- Digital Twins simulate full facilities before construction

- AI optimizes layouts, predicts operability issues, and tests scenarios

- Automated RBI tools assign inspection priorities

- Virtual commissioning reduces startup risks

Results:

- 30–50% fewer design iterations

- Earlier detection of constructability issues

- Faster decision cycles

By 2027, nearly 40% of major projects are expected to apply AI-assisted FEED workflows.

8. FEED in the Energy Transition Era

FEED is no longer just about hydrocarbons.

Today it must also accommodate:

- CCUS readiness

- Hydrogen blending

- Electrification interfaces

- Waste-heat recovery

- Modular expansion strategies

Governments increasingly link subsidies and incentives to technically mature FEED packages—especially for decarbonization retrofits.

This is giving rise to “Green FEED”: designs that embed low-carbon pathways from day one.

9. Best Practices for High-Performance FEED

- Multidisciplinary integration from Day 1 (process, piping, civil, integrity)

- Early 3D modeling and clash detection

- Structured value engineering workshops (10–15% savings typical)

- Regular gated stakeholder reviews

- RBI embedded during layout development

- KPI dashboards tracking estimate accuracy and risk closure

Common Pitfalls to Avoid

- Rushed scopes

- Siloed engineering teams

- Deferred safety studies

- Incomplete site investigations

10. Future Outlook: FEED as a Strategic Advantage

By 2030, FEED will evolve into a fully digital, sustainability-driven discipline:

- AI-optimized layouts

- Integrity-led design as standard

- Hydrogen and CCUS baked into base cases

- Digital twins used continuously from FEED through operations

Organizations that master FEED will consistently deliver:

Lower CAPEX

Faster schedules

Safer facilities

Reduced lifecycle cost

Transition-ready assets

Takeaway

FEED is not a paperwork phase.

It is the financial, technical, and operational foundation of every oil & gas project.

Strong FEED transforms uncertainty into engineered certainty—turning megaproject risk into competitive advantage.

In an era of volatile markets and energy transition pressures, projects don’t fail in construction—they fail in FEED.

Invest early. Engineer deeply. Your assets depend on it.