Why Corrosion Monitoring and Inspection Planning Is Critical for Asset Life Extension

In oil & gas, refineries, petrochemicals, and heavy industrial facilities, corrosion is not just material degradation—it is a direct threat to asset integrity, operational continuity, regulatory compliance, and corporate reputation.

Corrosion monitoring and inspection planning form the backbone of Asset Integrity Management (AIM) programs. When properly integrated, they allow operators to extend asset life safely, reduce downtime, optimize maintenance budgets, and meet increasingly strict regulatory requirements.

The Hidden Enemy: Understanding Corrosion’s True Impact

Corrosion often progresses silently beneath insulation, inside pipelines, or within process vessels. By the time visible damage appears, significant wall loss may already have occurred.

Globally, corrosion costs industries an estimated 3–4% of GDP annually, with oil and gas facing even greater risks due to:

- High pressure and temperature operations

- Sour service environments (H₂S/CO₂)

- Offshore marine exposure

- Produced water contamination

- Microbiologically Influenced Corrosion (MIC)

Major industrial failures worldwide have demonstrated how small corrosion mechanisms can escalate into catastrophic outcomes when left unmanaged.

Corrosion is highly variable. Its rate depends on:

- Temperature fluctuations

- Flow regime (laminar vs turbulent)

- Water cut and salinity

- Chemical injection performance

- Microbial activity

- Material selection

Without continuous monitoring and structured inspection planning, operators rely on reactive maintenance — a strategy that inevitably leads to unplanned shutdowns.

Why Asset Life Extension Is Now a Strategic Imperative

Energy infrastructure worldwide is aging. Many facilities operating today were originally designed for 20–25 years but are now expected to function for 40+ years.

Asset life extension is driven by:

- Capital expenditure reduction

- Energy transition pressures

- Sustainability goals

- Delayed greenfield investments

- Emissions reduction targets

However, extending asset life without integrity assurance increases risk exposure.

This is where API 580 and API 581 Risk-Based Inspection (RBI) frameworks become critical. RBI enables operators to prioritize inspection efforts based on:

- Probability of Failure (PoF)

- Consequence of Failure (CoF)

Instead of inspecting everything equally, high-risk equipment receives focused attention — improving safety while optimizing cost.

Well-implemented programs have demonstrated:

- 20–30% improvement in uptime

- 30–60% reduction in inspection costs

- 10–20 years of safe life extension

Corrosion Monitoring: The Real-Time Early Warning System

Corrosion monitoring provides continuous or periodic data on metal loss and degradation trends.

Common Monitoring Techniques

- Corrosion Coupons – Measure average corrosion rate over time.

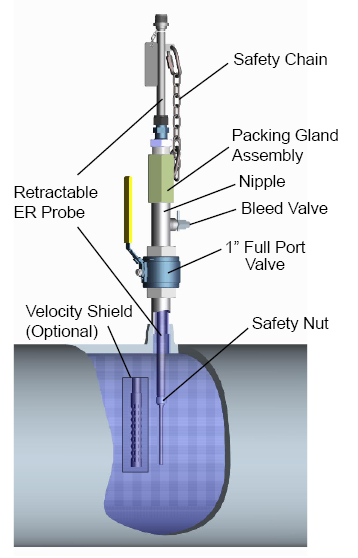

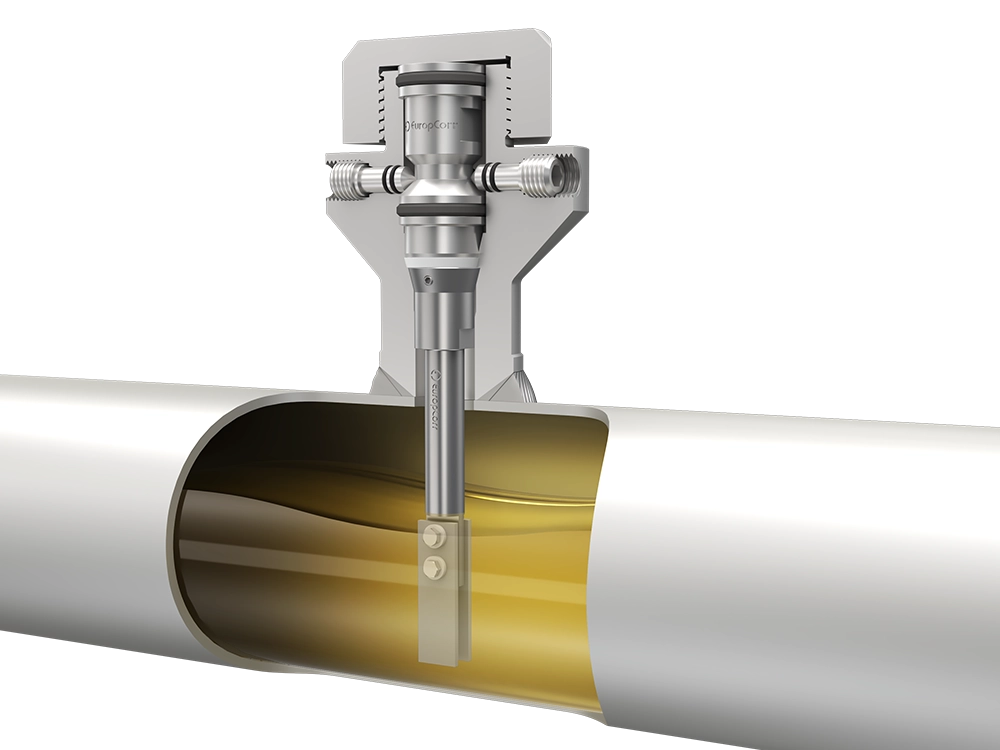

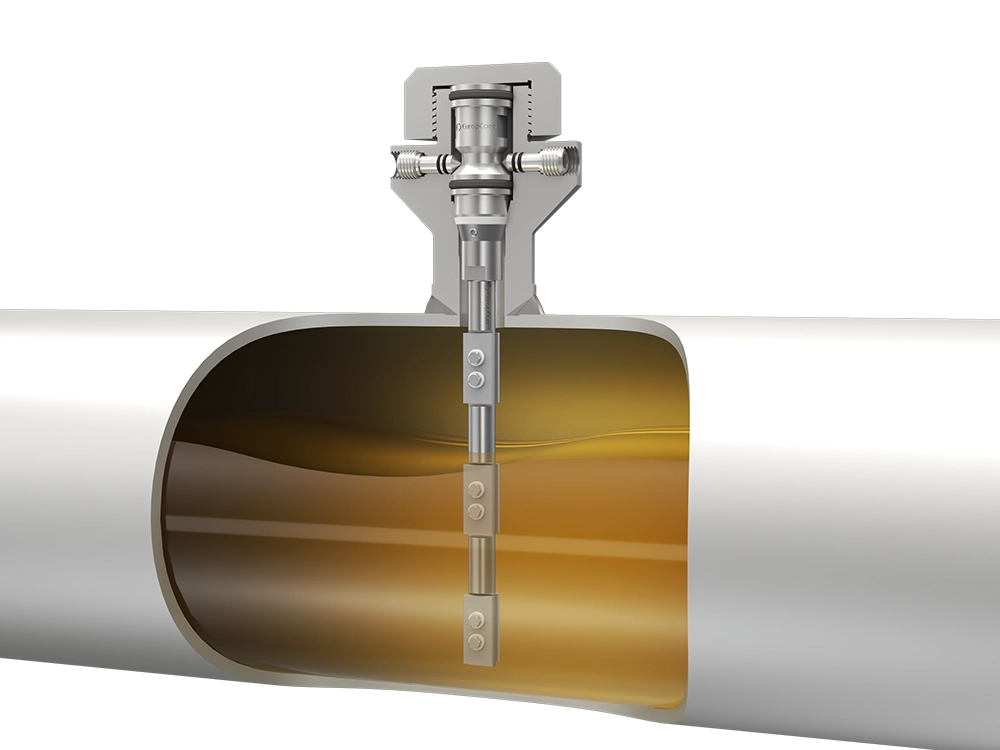

- Electrical Resistance (ER) Probes – Detect real-time metal loss.

- Linear Polarization Resistance (LPR) – Measure instantaneous corrosion rates.

- Hydrogen Probes – Detect hydrogen permeation in sour service.

- Ultrasonic Thickness Sensors – Monitor wall loss without shutdown.

- Field Signature Monitoring (FSM) – Detect localized corrosion.

For example:

If monitoring shows corrosion increasing from 5 mpy to 50 mpy due to process upset, corrective action (e.g., inhibitor optimization) can be taken immediately — long before Minimum Allowable Wall Thickness (MAWT) is reached.

Key Benefits

- Predictive failure forecasting

- Data-driven maintenance planning

- Reduced unnecessary inspections

- Improved chemical treatment optimization

- Enhanced environmental protection

Continuous monitoring can reduce inspection costs by up to 40% by identifying actual hotspots instead of relying on blanket inspection schedules.

Inspection Planning: From Reactive to Risk-Based Strategy

Inspection planning converts monitoring data into structured action.

Traditional inspection follows fixed intervals. Modern inspection uses risk-based methodologies guided by:

- API 510 – Pressure Vessels

- API 570 – Piping Systems

- API 653 – Storage Tanks

Steps in Effective Inspection Planning

- Baseline Assessment

- Initial UT mapping

- Radiographic weld inspection

- Material verification

- Risk Ranking (RBI Model)

- Calculate PoF × CoF

- Prioritize high-risk circuits

- Technique Selection

- Phased Array UT

- Eddy Current Testing

- Digital Radiography

- CUI inspection methods

- Interval Optimization

- Low corrosion rate (<0.5 mpy): extend interval

- High corrosion zones: increase frequency

- Digital Integration

- Link inspection results to CMMS

- Use digital twins for life prediction

- Calculate Remaining Useful Life (RUL)

Modern RBI programs often reduce inspection scope by 50% while maintaining or improving safety.

The Synergy: Monitoring + Inspection = Intelligent Integrity

Corrosion monitoring alone provides data.

Inspection planning alone provides structure.

Together, they create a closed-loop integrity management system:

- Monitoring detects rate changes

- RBI recalculates risk

- Inspection scope adjusts accordingly

- Mitigation actions are implemented

- Monitoring validates effectiveness

This integration is fundamental to advanced Integrity Asset Management (IAM) systems.

With emerging AI and machine learning tools, corrosion trends can now be correlated with:

- Weather changes

- Process throughput

- Flow velocity shifts

- Chemical injection performance

Predictive analytics is rapidly becoming standard practice in large operators.

Advanced Technologies Transforming Corrosion Management

The next generation of corrosion control includes:

- Wireless IoT corrosion sensors

- AI-driven anomaly detection

- Robotic crawlers for in-service inspection

- Fiber-optic distributed sensing

- Digital radiography systems

- Hydrogen embrittlement monitoring tools

These technologies are particularly critical for hydrogen and CO₂ transport pipelines in the energy transition era.

The Cost of Ignoring Corrosion

Failure to implement structured corrosion monitoring and inspection planning can result in:

- Accelerated wall loss

- Unexpected leaks or ruptures

- Environmental penalties

- Regulatory non-compliance

- Production downtime

- Reputational damage

Example calculation:

A pipeline with 20 mm wall thickness corroding at 1 mm/year theoretically reaches critical thickness in 20 years.

However, when safety factors and localized corrosion are considered, safe life may reduce to 8–12 years.

Reactive maintenance typically results in 2–5x higher lifecycle cost compared to proactive integrity programs.

Implementation Roadmap

To build a robust corrosion management system:

- Conduct asset integrity audit

- Identify corrosion circuits

- Install monitoring at critical points

- Develop RBI-based inspection plan

- Integrate with CMMS/digital platform

- Train inspection and corrosion teams

- Review and update annually

Partnership with certified NDT providers and corrosion specialists ensures program sustainability.

Future Outlook: Corrosion in the Energy Transition

As industries adopt hydrogen, CCUS, and higher-pressure CO₂ transport, corrosion risks evolve:

- Hydrogen-induced cracking (HIC)

- Stress-Oriented Hydrogen Induced Cracking (SOHIC)

- CO₂ corrosion in carbon capture pipelines

Monitoring systems must adapt accordingly.

Asset life extension will no longer be optional — it will be a competitive advantage.

Corrosion monitoring and inspection planning are not maintenance add-ons.

They are strategic investments in safety, sustainability, and long-term profitability.

Organizations that integrate real-time monitoring with risk-based inspection frameworks consistently achieve:

- Extended asset life

- Reduced operational risk

- Optimized inspection budgets

- Improved environmental protection

- Higher stakeholder confidence